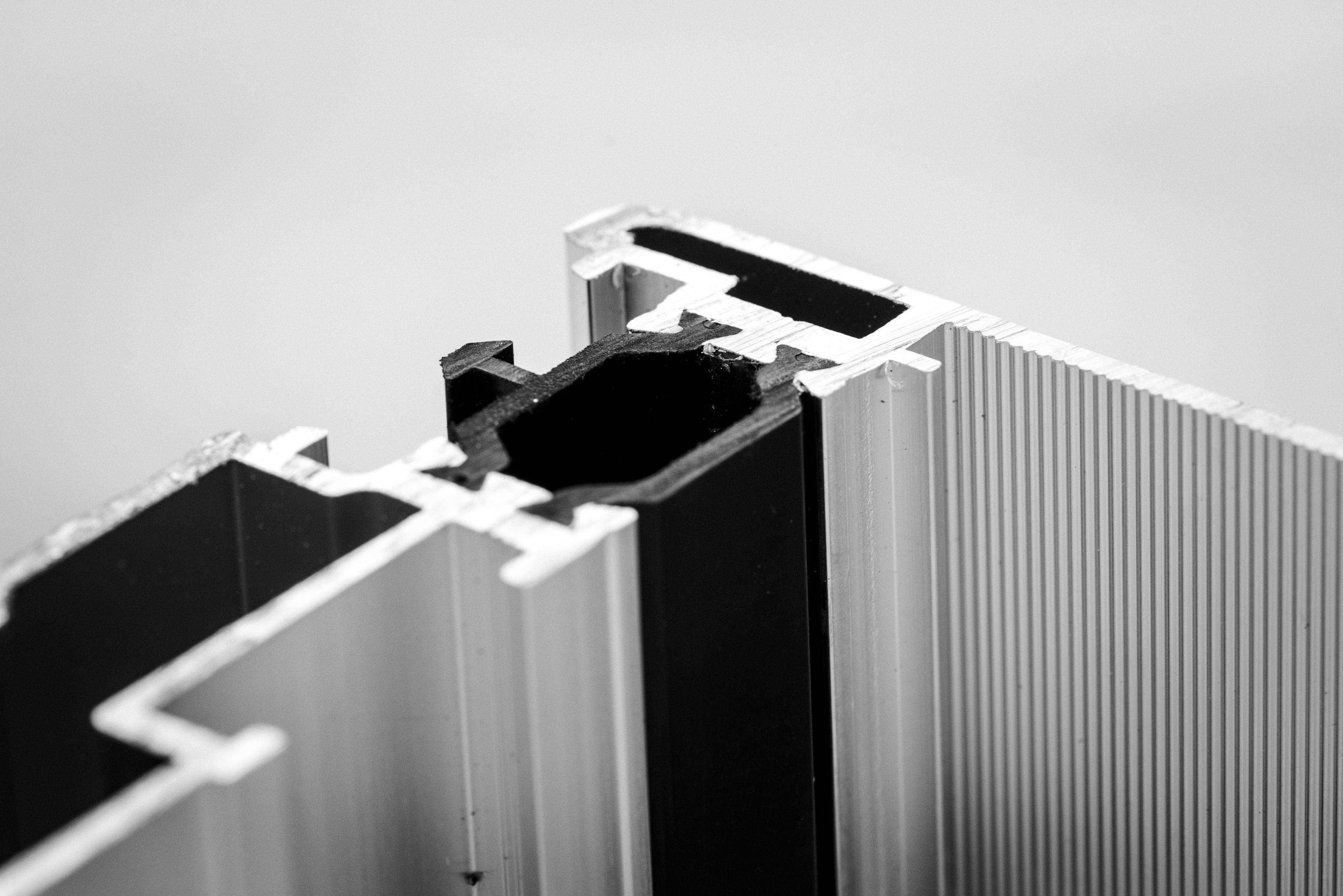

Thermal insulation for aluminium profiles

The creation of a thermal break is obtained with the following 3 main processes:

Process 1: Knurling

In order to obtain a highly stable profile, the insulation grooves on the inner and outer profiles are serrated (also called knurling).

Process 2: Assembling lines

With this process, the strips are inserted in the inner and outer profiles.

Process 3: Rolling or crimping

In this last process, the aluminium extrusions and the thermal strip are rolled under high pressure, so that the profile is fixed on position and meets the desired technical requirements.

Production lines

Our recently built offices and production facility are located near Antwerp, on a 15,000m2 lot.

In our production facility we use an extensive and modern range of machinery, including conventional and CNC-controlled roll-in lines. This enables us to provide all sizes with an accurate, efficient and very high quality thermal break.

Our "drive through", in combination with the various loading and unloading options with roller cranes (up to 3.2 tons) and side loaders (up to 3.5 tons), ensures optimal and fast handling of deliveries and pick-ups.